Patents for December/January

Patents as compile by the editors for Fastener Technology International from USPTO in December.

Joint Device for Screw and Nut

US Patent 11499584

Issued November 15, 2022

Inventor: Yi-Chang Wu, Taoyuan, Taiwan

A joint device for screw and nut includes a first body and a second body. The first body is provided with a plurality of first internal threads, of first external threads, and a first protrusion. The first protrusion is extended with a first engaging portion. The second body is provided with a plurality of second internal threads, of second external threads, and a second protrusion. The second protrusion is extended with a second engaging portion, such that the first protrusion and the second protrusion can be engaged with each other. When in a joining status, the first engaging portion and the second engaging portion are engaged with each other, such that the first body and the second body are folded up and around the screw. The nut can therefore screw up the first body and the second body correspondingly.

Fastener and Installation Method for Very Thin Sheets

US Patent 11498166

Issued November 15, 2022

Inventor: Michael J. Maloney, Doylestown, PA, USA; and Brian G. Bentrim, Furiong, PA, USA

Assignee: Penn Engineering & Manufacturing Corp., Danboro, PA, USA

A clinch-in fastener with a cylindrical body having a top, a bottom, sides and an axial internal bore. The fastener has a single shank at the bottom end of the body having a top surface orthogonal to the bore and a chamfer tapering to the bottom of the body. The top surface of the shank is adapted for receiving the cold flow of material surrounding a receiving hole of a workpiece. The shank may have a plurality of notches in its outermost edge that extend through both the top surface of the shank and the chamfer. The bore of the fastener extends completely through the fastener body from top to bottom and may be threaded. A fastener installation system having a tool with means for affixation to a rotary and vertically reciprocal element of an industrial machine. The tip of the tool has a distal end face with at least one arcuate displacer adapted for deforming a workpiece as the tool rotates and is pressed against the workpiece. A bore within the tip holds a fastener installed by the tool. The displacer is vertically and radially tapered along an arcuate ridge centered about the axial bore. The width of the displacer is also tapered to a point.

Bolt For Fastening Components, or the Ground Connection of Electrical or Electronic Components, on a Vehicle Body, a Bolt Arrangement Having a Bolt, and a Method for Forming the Bolt Arrangement

US Patent 11498160

Issued November 15, 2022

Inventors: Gerhard Brenninger, Schwindkirchen, Germany; Thomas Engelberger, Au in der Hallertau/Osterwaal, Germany; and Hannes Vasold, Schweitenkirchen, Germany

Assignee: Bayerische Motoren Werke AG (BMW), Munich, Germany

A bolt is provided for fastening a component or a ground connection of electrical or electronic components to a vehicle body. The bolt has a head portion with an external thread, the head portion being formed from a steel material, and a foot portion. The foot portion is formed from an aluminum alloy and is connected integrally to the head portion by a friction-weld connection. The bolt is configured in the form of a welding stud for drawn arc stud welding, for which purpose it has an ignition tip on its end side, which delimits the foot portion.

Anti-Loosing Bolt Component Capable of Presetting Torque and Controlling Disassembly

Us Patent 11499586

Issued November 15, 2022

Inventor: Zuoyu Gong, Guigang, China

The disclosure relates to an anti-loosing bolt component capable of presetting torque and controlling disassembly, including: a nut, a bolt and a tab washer that match each other. The nut is provided with a ratchet structure, the bolt is provided with an axial groove, and the tab washer is provided with a elastic pawl matched with the ratchet structure, and a horizontal protrusion provided with a prefabricated notch and matched with the axial groove. The ratchet structure adopts a matching mode that the difference between the number of ratchets and the number of the elastic pawls is 1, so that the nut can be engaged by a very small rotation angle. The preset torque of the prefabricated notch can be set according to a safety factor. The bolt component can be accurately prevented from loosening.

Fastener

US Patent 11499585

Issued November 15, 2022

Inventor: Douglas E. Hersh, San Diego, CA, USA

Assignee: Sentient Design, Inc., San Diego, CA, USA

A nut-and-bolt fastener is provided. The nut and bolt are configured with a plurality of interlocking teeth that provide unidirectional travel of the nut with respect to the bolt. In particular, the configuration of the teeth arrest separation of the nut from the bolt while permitting the nut to move toward the head of the bolt into a fastened engagement. The teeth are non-helical and arranged concentrically around the longitudinal axis in evenly-spaced steps or segments along the longitudinal axis and around the shaft of the bolt and bore of the nut. Integral winged washers are provided on the bolt head as well as on the nut. Variations with different rake angles of the teeth as well as an expandable nut are also provided.

Fastener Assembly

US Patent 11499583

Issued November 15, 2022

Inventor: Earl Allen Size, Jr., Rochester Hills, MI, USA

A fastener assembly having a nut with interior threads extending from a first end to an intermediate end wall, a narrowed diameter aperture extending from the end wall toward a second end. A first screw has a shaft exhibiting a first exterior thread pattern rotationally inter-engaging with the interior threads of the nut when installed through the first end. A recess formed in an end of the shaft exhibiting a further plurality of interior threads matching a direction of the first thread pattern. A second screw has a second exterior thread pattern opposite the first pattern and, upon being installed through the narrowed aperture, rotationally inter-engaging the interior threads of the first screw, with loosening of either screw being prevented by their counter-threaded orientation. A head of the second screw exhibiting an outer annular rim establishing a resistance fit within an entranceway location of the nut.

Torque Limiting Screw

Us Patent 11493075

Issued November 8, 2022

Inventors: Michael Maloney, Doylestown, PA, USA; and Robert Stotz, Jr., Sellersville, PA, USA

Assignee: Penn Engineering & Manufacturing Corp., Danboro, PA, USA

A compound screw is a two-piece assembly where the head of the screw can rotate in the tightening direction to a designed tightening torque to drive the screw while being able to positively counter-rotate in the loosening direction. The screw assembly comprises a screw and a cap surrounding the head of the screw. The screw has a head at the top and a threaded shank downwardly extending from a base of the screw head. The screw is turned by turning the cap about a central axis of the screw. The cap is rotatably affixed to the screw head by a loose riveting of the cap to the top most end of the screw head by flaring a thin-walled upwardly extending portion thereof. The cap includes a plurality of axially extending peripheral resilient arms which engage peripheral cam surfaces around the outside of the screw head.

Self-Drilling Screw

US Patent 11486433

Issued November 1, 2022

Inventors: Kou-Tsair Su, Kaohsiung, Taiwan; and Yu-Jung Su, Kaohsiung, Taiwan

Assignee: Taiwan Shan Yin International Co., Ltd., Kaohsiung, Taiwan

A self-drilling screw includes a leading section having a drill body and opposite discharge grooves formed on the drill body. The drill body and the discharge grooves meet at cutting edges. On the drill body are formed two blade portions connected to the cutting edges and tapering at respective second tips. The blade portion has a second included angle of not more than 50 degrees. Between the blade portions is formed a drilling portion terminating at a first tip and having a first included angle of not more than 60 degrees. Two opposite concave surfaces each extend from the drilling portion to each blade portion. The first tip and the second tips are situated at different places. Accordingly, the end of the leading section presents a shape of a curved bow riser to cut quickly and help quick removal of chips, thereby decreasing resistance and preventing the cracking problem.

Method and Device for Monitoring the Clamping of an Assembly by a Threaded Fastener

US Patent 11486781

Issued November 1, 2022

Inventors: Clément Chirol, Trebons sur la Grasse, France; Patricia Morgue, Colomiers, France; Manuel Paredes, Balma, France; and Simon Dols, Toulouse, France

Assignee: Airbus Operations SAS, Toulouse, France

A device for monitoring clamping of an assembly including at least one part to be clamped, an internally threaded element and an externally threaded element engaged in an internal thread of the internally threaded element. The device includes a driver to rotate one of the elements including the internally threaded element and the externally threaded element to clamp the assembly and a first sensor to measure a screwing torque of the driver, a tool for holding fixed against rotation the other of the elements including the internally threaded element and the externally threaded element, a second sensor to measure a reaction torque of the holding tool, a mechanism for determining a third parameter chosen from a time elapsed from a given time and a screwing angle from a reference position, and a calculation system to determine pre-tension in the externally threaded element.

Molding Die Structure for Forming Oblique Teeth on a Rivet Nut

US Patent 11471930

Issued October 18, 2022

Inventor: Ming-Che Kuo, Tainan, Taiwan

Assignee: Wei In Enterprise Co., Ltd., Tainan, Taiwan

A molding die structure for forming oblique teeth on a rivet nut includes a mold seat, a first forging die, a second forging die, and a retaining member. The mold seat is provided with a mold cavity and a threaded portion. The first forging die is inserted into the mold cavity and provided with a die cavity and a nut cavity. The second forging die is inserted into the die cavity and has an inner face provided with an oblique toothed portion and a guide hole. The oblique toothed portion includes a plurality of oblique teeth. The retaining member is screwed into the threaded portion and limits the first forging die and the second forging die in the mold cavity. The second forging die and the die cavity of the first forging die form a low friction contact.

Nut Locking System with Different Threads Sharing Same Pitch

US Patent 11473611

Issued October 18, 2022

Inventor: Keith Stewart, Inman, SC, USA

A locking nut system includes a threaded member with a first threaded area having a first thread direction and a second threaded area having a second thread direction opposite the first thread direction in which a plurality of crests extend across the first and second threaded areas with a constant pitch between the crests such that minimal material is removed, structural integrity is maintained, and a first nut secures the threaded member to a workpiece and a second opposing nut renders the first nut stationary.

Rivet Dispensing Systems and Methods of Use Thereof

Us Patent 11471932

Issued October 18, 2022

Inventors: Daniel Peter Vanderzwet, Omemee, ON, Canada; Simon Maurice Britton, Windsor, ON, Canada; Larry Frank Koscielski, LaSalle, ON, Canada; Eric Jean Michaud, Amherstburg, ON, Canada; David Mario Simone, Amherstburg, ON, Canada; Donald J. Spinella, Greensburg, PA, USA; Gino N. Iasella, Pittsburgh, PA, USA; Daniel Bergstrom, Sarver, PA, USA; Robert B. Wilcox, McGregor, TX, USA; Thomas R. Kingsbury, Waco, TX, USA; and Graham Scott Musgrove, Waco, TX, USA

Howmet Aerospace Inc., Pittsburgh, PA, USA

Rivet dispenser systems and methods of use thereof are provided. In a non-limiting embodiment, the rivet dispenser system comprises a rivet receiving member defining a channel therein, and a seat member. The channel includes a curved region. The rivet receiving member comprises a first port and a second port. The first port communicates with the channel and is configured to receive rivets. The second port communicates with the channel and is configured to dispense rivets. The channel extends between the first port and the second port and is configured to transport rivets from the first port to the second port in a series arrangement and in a preselected orientation. The seat member communicates with the second port and is configured to selectively engage with a rivet holder of a resistance spot rivet welding apparatus and introduce a single rivet to the rivet holder at one time.

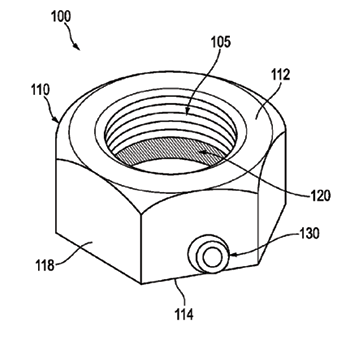

Sealant Injection Nut

US Patent 11460131

Issued October 4, 2022

Inventors: Saad M. Alshiha, Dhahran, Saudi Arabia; Bader M. Jarallah, Dammam, Saudi Arabia; and Hassan A. Alsalloum, Dammam, Saudi Arabia

Assignee: Saudi Arabian Oil Company, Dhahran, Saudi Arabia

Systems and methods for sealing bolted flange joints to stop or prevent leakage are disclosed. The system includes a sealant injection nut. The sealant injection nut generally comprises a threaded nut configured to be threaded onto a stud bolt of a flange joint. The nut is configured to inject sealant into the internal passages of the flange joint. The nut includes a passageway drilled through the sidewall. Fitted to the passageway is a high-pressure sealant-compatible injection fitting and an internal check-valve. Provided within the central cavity of the nut, at the flange-facing end, is a groove that facilitates the flow of sealant injected through the passageway into the passages of the bolted flange. A method is also provided for manufacturing the sealant injection nut. A method is also provided for repairing leaking bolted flange joints using the sealant injection nut.

Eco-friendly Fastener Structure with Lockable Stainless Steel Screw Pair

US Patent 11454272

Issued September 27, 2022

Inventor: Chien-Fang Yang, Pingtung County, Taiwan

The two lockable stainless and lossless screw pairs at two ends of the bolt are provided both to avoid screw pairs stained or destroyed by strain force from loading and to decrease the cost because of energy consumption in traditional process of bolt or its cost from environmental pollution.

Retained Self-aligning Washer and Nut Assembly and Method for Fabrication by Additive Manufacturing

US Patent 11448254

Issued September 20, 2022

Inventors: Marc Storozuk, Winnipeg, Canada; and Richard W. Aston, Brea, Canada

Assignee: The Boeing Company, Chicago, IL, USA

A washer and retained nut assembly has a washer with a retaining flange and a positioning cavity and a nut received in the washer. The nut has a shoulder received in the positioning cavity with a top surface of the shoulder engaging a lower surface of the retaining flange in a loose condition of the washer and nut. The nut further has an engagement surface contacting a receiving surface in the washer in an engaged position of the washer and nut. The nut further has a peripheral surface engaging a blocking surface in the washer with the nut and washer in a maximum offset angle orientation between the washer and nut in the engaged position.

Terminal for a Secondary Cell and a Terminal Rivet

US Patent 11450933

Issued September 20, 2022

Inventor: Myungjae Jang, Stockholm, Sweden

Assignee: Northvolt AB, Stockholm, Sweden

This disclosure presents a terminal (30) for a secondary cell (40). The terminal (30) comprises a terminal plate (20) comprising a through-hole (21) and an inner surface (23) adapted to face the interior of the secondary cell (40). The terminal (30) further comprises a terminal rivet (1) that extends through the through-hole (21) of the terminal plate (20). The terminal rivet (1) comprises a first flange (6) that comprises a protruding portion (7), and the protruding portion (7) extends into the inner surface (23) of the terminal plate (20) in a riveted state (1b). The disclosure also presents a terminal rivet (1).

Positive Locking Fastener

US Patent 11448253

Issued September 20, 2022

Inventors: Mohamed Abou Halima, Gennevilliers, France; and Loic Meiffre, Conflans Sainte-Honorine, France

Assignee: LISI Aerospace, Paris, France

The invention relates to a positive locking fastener comprising: a screw (1) having a radial hole (120) at a threaded portion (12); a nut (2) having a tightening portion (21); a cap (3); and a pin (4). The cap has a locking portion (31) intended to cover the threaded portion and a blocking portion (30) intended to engage with a tightening portion of the nut. The blocking portion comprises at least one pair of diametrically opposed openings (32) suitable for allowing a pair of openings to be aligned with the radial hole, in order to allow the pin to be inserted and thus lock the fastening regardless of the relative position of the nut with respect to the screw. The invention also relates to a method for implementing the fastener according to the invention.