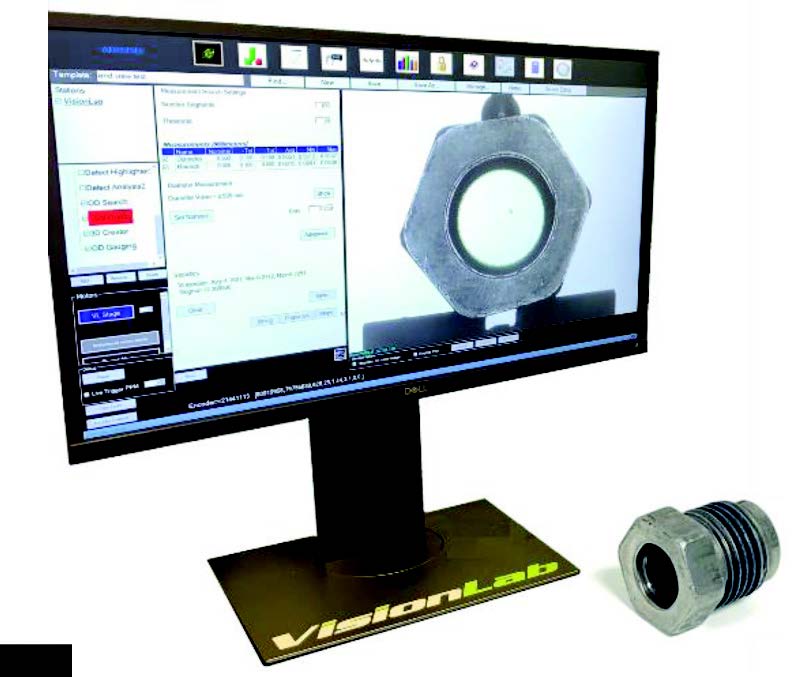

New 3D Gauging System

by: Greg Nygaard, VP Sales General Inspection, LLC

Added dimensional inspection capabilities, optional surface defect detection and optional end-view and through hole inspection.

For many fastener-related businesses including manufacturers, distributors and end users, the

inspection process has long been an expensive bottleneck, requiring extensive investment in

gauges and related tools as well as high employee hours. In 2006, General Inspection (Gi) pioneered

3D part inspection with the patented gauging system, LaserLab. The system successfully performed

inspections in many industries both in lab and shop floor environments and continues to serve Gi’s

extensive customer base today.

The LaserLab was a huge success for General Inspection and its users. The system was a pivotal

development for the growth of businesses that utilize the system and propelled Gi’s R&D efforts to

advance to the next generation of 3D gauging technology.

As with many products, the next generation developments can be game changers, i.e., flip phones

to smart phones. Gi expects the same impact from its newly released VisionLab 3D gauging system

with added dimensional inspection capabilities, optional surface defect detection and optional end view and through hole inspection.