Patents for June 2024

USPTO Fastener Patents Compiled from: United States Patent and Trademark Office (USPTO) by the editors of FTI for June 2024

Anchor Bolt Assembly and Ceiling Finishing Panel Fixing Apparatus Comprising Same

US Patent 11987980

Published May 21, 2024

Inventor: Ju Byeong Cha, Seoul, South Korea

An anchor bolt assembly according to an embodiment of the present

disclosure includes an anchor body provided with a plurality of pointed

protrusions on an upper surface thereof, an anchor shell provided with

open upper and lower sides thereof, extrapolated to a lower side of the

anchor body, provided with a first incised part having a “Y” shape at an

equal interval along a circumference of the anchor shell, and provided with

a second incised part having a “v” shape at an equal interval along a

longitudinal direction of the first incised part, a tightening member screwed

to the anchor body through a screw thread provided on an inner

circumferential surface of the tightening member, and provided with a

processing part for increasing frictional force along an upper circumference

of the tightening member.

Bolt and Fastening Structure

US Patent 11988238

Published May 21, 2024

Inventors: Yuichiro Suzuki, Niwa-Gun, Japan; Mitsuki Yoshida, Niwa-Gun,

Japan; Akihiro Furukawa, Niwa-Gun,

www.uspto.gov

Japan: and Yukinori Fujimoto, Niwa-Gun, Japan

Assignee: Aoyama Seisakusho Co., Ltd., Niwa-Gun, Japan

To threaded engage a bolt and a female screw with each other, thereby

making it possible to shave off a deposit on the inner surface of the female

screw and to make it easy for a worker to sense the seating, there is

provided a bolt including a shaft 2 and a head, wherein a first thread 11 is

provided on a head side of the shaft, and at least one of a thread provided

larger in diameter than the first thread and a thread provided wider than

the first thread is provided on a tip end side of the shaft.

Screw Nut and Electronic Device Having the Same

US Patent 11988239

Published May 21, 2024

Inventors: Hsin-Chuan Hsu, New Taipei, Taiwan; and Ming Chun Wang, New

Taipei, Taiwan

Assignee: Wistron Corp., New Taipei, Taiwan

An electronic device has a screw nut. The screw nut is configured for fixation

of a fastener. The screw nut includes an inner nut component, a cushioning

component and an outer nut component. The inner nut component has a

screw hole portion configured for fixation of the fastener. The cushioning

component is sleeved on the inner nut component. The outer nut

component is sleeved on the cushioning component. The cushioning

component is connected between the inner nut component and the outer

nut component so that the inner nut component is movably connected to

the outer nut component.

Locking Tab-Washer

US Patent 11988240

Published May 21, 2024

Inventors: David Pyra, Longueuil, Québec, Canada; Guy Lefebvre, SaintBruno-de-Montarville, Québec, Canada: and Gerard Theriault, Longueuil,

Québec, Canada

Assignee: Pratt & Whitney Canada Corp., Longueuil, Québec, Canada

A locking tab washer for rotatably locking a bolt fastened to a component in

an aircraft engine has a body with an opening and at least four locking tabs

positioned about the opening and circumferentially spaced apart from one

another at integer multiples of a common angle relative to the center of the

opening. The locking tabs are bendable towards to rotatably lock the bolt.

The locking tab washer also has a retaining feature positioned about the

opening and operable to rotatably retain the locking tab washer to the

component.

Osteosynthesis Device with Plate Provided with a Threaded Hole for

Receiving a Locked Fastening Screw

US Patent 11974790

Published May 7, 2024

Inventors: Julien Ballerini, Nantes, France; Grégoire Larche, Cholet, France;

and Jean-Pierre Podgorski, Sevremoine, France

Assignee: Newclip International, Luxembourg

In an osteosynthesis device with a plate and a screw for fixing the plate on a

bone, the head of the screw includes a thread for its locking with the

internal thread in its receiving hole. The internal surface of the plate hole

includes a first frustoconical section that extends at an angle 30-60° with

respect to the hole central axis, and a second frustoconical section that

extends between the first frustoconical section and the plate lower face, at

an angle 8-12° with respect to the hole central axis. The internal surface of

the hole also includes at least three upper undercuts, and at least three

lower undercuts, which upper and lower undercuts allow a degree of

freedom in angulation of the screw, and also preserve a portion of hole

internal thread on all the generatrices of the hole internal surface located in

planes parallel to the central axis.

Remote Monitoring and Actuation of Fasteners

US Patent 11975426

Published May 7, 2024

Inventor: Christopher V. Beckman, Miami, FL, USA

Improved techniques for remotely monitoring and managing fasteners and

fastener driver conditions, are provided. In some aspects of the invention,

conditions of a fastener and/or structural material(s) held by the fastener

and/or connector, are monitored by a control system including sensor(s) at

least partially embedded in, on or throughout the fastener and/ or

structural material(s). When an adverse condition is sensed, a torque may

be remotely applied to the fastener, in some embodiments. In some

embodiments, other remedial actions may be taken by the control system.

In some embodiments, such sensor(s) include a magnetizable array, which

may include one or more charge-carrying and/or otherwise magnetic wires

or particles on, about, or embedded within, the fastener and/or structural

material. In some embodiments, such remote monitoring includes testing a

magnetic signature of the fastener and/or structural material (e.g., via

remote scanning and/or testing).

Titanium Alloy Fastener and Manufacturing Method

US Patent 11971063

Published April 30, 2024

Inventor: Guillaume Leger, Villiers-Adam, France

Assignee: LISI Aerospace, Paris, France

The invention relates to a fastener comprising a substantially right circular

cylindrical surface arranged along an axis, said surface comprising a

grooved shape selected from a thread, a tapping and a plurality of traction

grooves, said fastener being made of a beta-metastable titanium alloy. The

alloy has a microstructure (40) made up of a matrix (42) and alpha phase

nodules (44) distributed in said matrix, the matrix being made up of beta

phase and groups (46) of alpha phase lamellae (48) oriented in the same

direction.

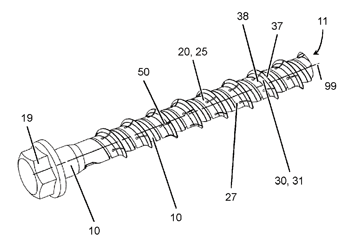

Expandable Screw with Separate Expansion Fingers

US Patent 11965535

Published April 23, 2024

Inventor: Roland Schneider, Schlins, Austria

Assignee: Hilti AG, Schaan, Liechtenstein

A screw includes a shank where a thread helix receiving groove winds

around the shank and is disposed in the shank. A thread helix is disposed in

the thread helix receiving groove where the thread helix has an expandable

helix section. The shank has, at the thread helix receiving groove, a wedge

flank for radially expanding the expandable helix section as the shank is

moved relative to the expandable helix section. The expandable helix

section has a helical back and a plurality of expansion fingers projecting

axially from the helical back towards the wedge flank. The wedge flank of

the thread helix receiving groove is configured for radially displacing the

plurality of expansion fingers outwardly as the shank is moved relative to

the plurality of expansion fingers.

Anti-Creep Anti-Back-Out Compact Fastener

US Patent 11965539

Published April 23, 2024

Inventor: Navid Poulad, San Jose, CA, USA

Assignee: Microsoft Technology Licensing, LLC, Redmond, WA, USA

An integrated fastener includes a threaded portion, a fastener head, and

one or more spring fingers integrated into the fastener head, wherein the

spring fingers are configured to apply a compressive load when the fastener

is inserted and secured to a receiving assembly.

Self-Forming Thread Blind Fastener

US Patent 11959504

Published April 16, 2024

Inventor: Thomas Brennetot, Conflans-Saint-Honorine, France

Assignee: Howmet Aerospace Inc., Pittsburgh, PA, USA

Self-forming thread blind fasteners and methods for fastening are provided.

The self-forming thread blind fastener comprises a sleeve and a pin. The

sleeve comprises a first sleeve end, a second sleeve end, an elongate

portion, and an inner wall defining a bore. The pin is configured to be at

least partially received by the bore. The pin comprises a first pin end, a

second pin end, a pin head portion, an at least partially threaded portion, a

shank intermediate and a driving portion. The at least partially threaded

portion is configured to form threads on at least a portion of the inner wall

of the sleeve. The driving portion is configured to receive a torque to rotate

the pin within the sleeve and thereby axially compress and deform the

sleeve and form the threads on the at least a portion of the inner wall of the

sleeve.

Small Fastener

US Patent 11953038

Published April 9, 2024

Inventor: Jan Niklewicz, Kingston Upon Thames, Great Britain

Assignee: Kwikbolt Limited, Middlesex, Great Britain

A removable blind fastener includes: a body; a screw member; and a

clamping member. The body includes a hollow cylindrical shaft with a

proximal end and a distal end and a head at the proximal end, the head

being hollow with an internal end face. The shaft has an open guide channel

along a portion of its length and an urge channel opposite the guide

channel located at the distal end of the shaft. The screw member has a

threaded region that fits within the shaft and the screw member has a head

at a proximal end that fits within the hollow head. The clamping member fits

in the guide channel and has a threaded aperture for engaging with the

threaded region of the screw member, such that rotation of the screw

member causes the clamping member to move along the guide channel of

the body.

Screw Thread

US Patent 11953045

Published April 9, 2024 Inventors: Shigeto Mori, Hadano, Japan; Mayumi

Matsuno, Hadano, Japan; and Naoki Horiuchi, Hadano, Japan Assignee:

Topura Co., Ltd., Hadano, Japan To provide a screw thread which achieves a

further reduction in screwing torque while securing removability of a

coating film or the like and which is capable of stabilizing conductivity. In a

screw thread in which a recessed portion (7) is partially provided on a flank

surface (131) of a screw thread ridge provided on a screw thread shaft main

body (5), a screw thread ridge (13) in a section where the recessed portion

(7) is formed is smaller than a regular screw thread ridge (3), and a ridge

height (H12) in a distal end portion in a screwing direction is lower than a

ridge height (H11) in a rear end portion in the screwing direction W.

Nut

US Patent 11953046

Published April 9, 2024

Inventors: Tetsuo Shibusawa, Tokyo, Japan; and Kenta Tasaka, Tokyo, Japan

Assignee: Iwata Bolt Co., Ltd., Tokyo, Japan

There is provided a nut in which occurrence of galling is prevented. The nut

in which a depth t of a counterbore hole is set to be greater than (Ddxcosɵ)/tanɵ, when a nominal diameter is D, an average value of a

maximum outer diameter and a minimum outer diameter taking into

account a tolerance of a bolt to be fitted is d [mm], an inner diameter of the

counterbore hole provided on an insertion side of a screw hole is D+0.2

[mm], a pitch of a screw thread is P [mm], and ɵ satisfies ɵ=arc tan(P/d).

Breakaway Threaded Fasteners and Electrical Connectors Having Such Fasteners

US Patent 11953043

Published April 9, 2024

Inventor: Dana Khalid Saeed, Lewisville, TX, USA

Assignee: Hubbell Incorporated, Shelton, CT, USA

A breakaway threaded fastener is provided. The fastener has a stud, a pin

and a cap. The stud has a hollow cavity with a closed end, an open end, a

wall and an outer surface. The outer surface has an external thread. The pin

is in the hollow cavity. The pin has a first end at the closed end of the stud

and a second end extending above the open end of the stud. The cap has

another hollow cavity with a closed end, an open end and an internal

thread. The cap is threadably engaged to the open end of the stud via the

internal and external threads so that the second end of the pin abuts the

closed end of the cap.

Toothed Washer

US Patent 11946578

Published April 2, 2024

Inventors: Josef Brandt, Wipperfürth, Germany; Frank Engelhard,

Wermelskirchen, Germany; Markus Waschkewitz, Bergneustadt, Germany;

Kazim Canpolat, Dormagen, Germany; and Adrian Klehr, Balve, Germany

Assignee: VOSS Automotive GmbH, Wipperfürth, Germany

A toothed washer, in particular for fixing a tube line introduced in a fluid

connector in an insertion direction, including an annular base having a

toothed washer central axis. At the inner circumference of the base, cutting

teeth are respectively disposed as a single component on the base radially

inward and obliquely to the toothed washer central axis and extending in

the insertion direction over an overmolded resilient hinge section and an

overmolded retaining section connected thereto. The cutting teeth are

configured such that in the event of a fixing movement of the tube line, the

cutting teeth cut-in against the insertion direction into an outer

circumference of the tube line, wherein the cutting teeth include a cutting

surface for cutting into the outer circumference of the tube line to be fixed.

The cutting teeth have a support surface, and the support surface is

configured set back radially outward as viewed from the cutting surface, so

that the cutting-in of the respective cutting tooth is limited during a placing

of the support surface onto the outer circumference of the tube line.

Furthermore, the invention relates to a fluid connector for tube line

installation, in particular fluid-guiding tube lines, including a receptacle

section for introducing a tube line in an insertion direction, as well as a

retaining element, configured as such a toothed washer, disposed in a

receptacle section.

Fastener

US Patent 11939999

Published March 26, 2024

Inventor: Jorg Blin, Wildeshausen, Germany

Assignee: Wheelguard GmbH, Wildeshausen, Germany

A fastener, in particular of a chassis component, has at least one sensor and

at least one transmitter of a monitoring device for monitoring at least one

mechanical fastening parameter. At least one power supply unit is

associated with the transmitter, that the transmitter and the power supply

unit are connected to one another by means of a switching contact, that an

electrical connection can be closed by means of the switching contact, that

the switching contact is designed in such a way that the electrical

connection is open when the fastener is installed properly and is closed only

when the fastener is released, and that the transmitter is supplied with

current and transmits a signal only when the electrical connection of the

switching contact is closed.

Spring Clamp with Installation and Removal Capability

US Patent 11739870

Published August 29, 2023

Inventor: Jerry Seimears, Renton, WA, USA

A spring clamp with integrated installation and removal capability allows a

user to install or remove the spring clamp safely using common shop tools

or by hand. The spring clamp includes two tangs with a fastener extending

between them. The fastener may be used to draw the tangs together or

apart, to thereby open or close the spring clamp, and to safely change the

potential energy of the spring clamp. The user may turn the fastener or a

nut on the fastener using common shop tools or by hand to expand the

spring clamp so that it can be slipped over a hose and to allow the spring

clamp to tighten around the hose.