Revolutionary Drive System Solves Difficult Assembly Challenges

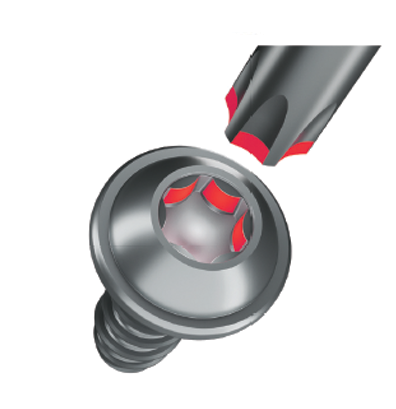

When it comes to assembling recessed fasteners several challenges commonly face assemblers; bits staying engaged in the recess, engaging non-ferrous fasteners, maximizing torque transmission from the bit to the fastener and longevity of drive bits. Although all of these challenges are common and potentially vexing, perhaps the one with the fewest available solutions is the ability to engage and hold the bit on non-ferrous screws.

For assemblers that rely on efficient and uninterrupted assembly processes of stainless steel, other nonferrous materials and miniature screws, difficulties engaging and the possibility of dropping of screws could prove untenable. Therefore, modern manufacturing often employs sophisticated and complex methods to guarantee that an internal recess head screw is delivered to the assembly point and successfully driven every time.