How Deflection Range Affects the Performance of Disc Springs

By John Leckfor Applications Engineer SPIROL Danielson, CT, U.S.A.

Disc Springs are conically shaped washers designed to provide predictable and repeatable performance. They may be used to either apply a static load, where the load is nearly constant, or in dynamic situations, where the Disc Spring is experiencing repeated loading and unloading. It is critical to understand how load characteristics affect performance to properly design a system that uses Disc Springs.

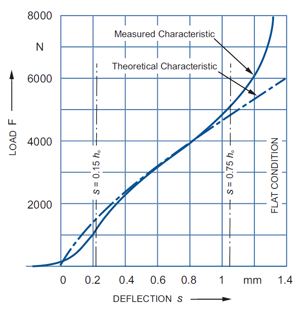

Springs are unlike other assembly components; they are designed to deflect and store mechanical energy. The deflection of a Disc Spring is predictable, making it possible to estimate the life cycle of a Disc Spring in an assembly. Optimal Disc Spring performance is achieved when working deflection is kept between 15% and 75% of full deflection. It is in this range that measured results most accurately match the theoretical characteristics of Disc Springs.