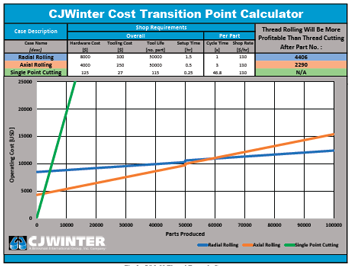

To Roll or Not to Roll? – That is the Question!

In recent months, I’ve often been asked a similar question: “How can one justify rolling versus cutting a thread?” As a technical and analytical person, I wanted to demonstrate with real, practical data how to justify one process over the other. As someone once told me, “Without good data, it’s just an opinion.” In our shops, are we using data, or going by “opinion?” I set out to determine the variables that govern this manufacturing process. Several key factors came to mind:

- Hardware Costs: Attachments, insert tool holders.

- Tooling Costs: Thread rolls, insert costs.

- Tool Life: Number of parts produced with one thread

roll or insert. - Process Setup Time: Time to install attachments or tool

holders. - Cycle Time: Time to produce a thread.

- Shop Rate: Cost of running an operation per hour.

Based on these variables, we developed a calculator to determine the cost performance of thread rolling (both Radial and axial style) versus single point process. With the assistance of a couple of engineers, we analyzed several use cases examples generated to show the applicability of our calculator to a range of applications.