Pickling and Coating Wire Rod: A Focus on Efficiency and Productivity

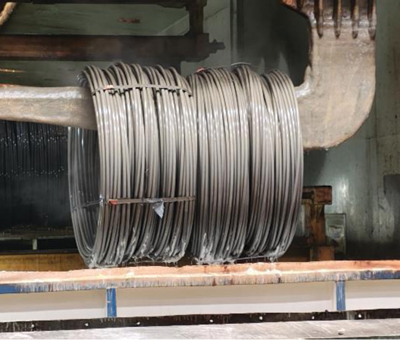

The pickling and coating of wire rod is a critical process in the automotive industry, demanding high efficiency and productivity to meet the industry’s stringent requirements. Let’s explore key strategies and technologies to optimize this process. Before delving into efficiency and productivity, it’s essential to understand the basic process: Pickling involves removing scale and impurities from the wire rod surface using acids. Rinsing follows, where acids are removed through multiple rinsing stages. Next, a protective coating, such as zinc or polymer, is applied to the wire rod surface. Finally, the coated wire rod is cooled to solidify the coating.