Streamline Cold Forging Design Using Design & Simulation Software

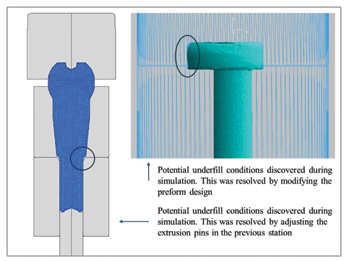

Manufacturing of a cold forged part requires design of forging sequence, selection of forging equipment, design of tooling and cold forging the part to strict quality and dimensional tolerances. In the past, cold forging processes have been developed through trial-and-error experimentation and experience gained on the forging machine. In today’s environment, this trial-and-error approach is not a cost-effective solution. We now have software, such as NAGFORM (Progression Design) and NAGSIM (FEA Simulation Software), to cut down the time it takes to perform any cold forging related task and thereby reduce the cost and time to develop any new product.