Environmentally Friendly Surface Hardening Replaces Hard Chrome Coatings

In general, coating methods that can prevent corrosion tend to add material and are often inconsistent in terms of the thickness of the applied layer. This can result in material accumulations on flat structures or material thinning at corners and edges where protection is reduced.

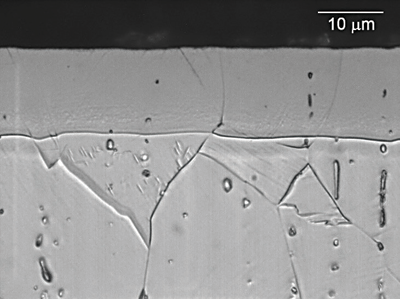

Additionally, coatings may crack and peel off during significant expansion or contraction of the base material due to differences in the thermal expansion coefficient between the base and the coating. Complex contours with undercuts and small openings pose additional challenges, and certain coating methods are not compatible with these surfaces. Expanite takes a different approach to this process that avoids these issues.