Fastener Testing

Alan Thomas, ZwickRoell Limited

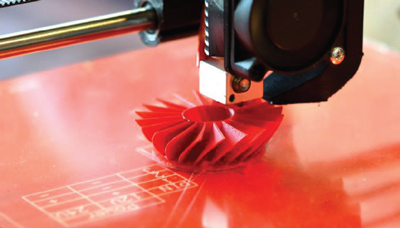

Testing Lends Crucial Support for Quality Management in Additive Manufacturing

The adoption of additive manufacturing (AM) as a viable means of production continues to increase, offering substantial advantages for the manufacture of low-volume, high-mix parts and complex geometries prohibitive under conventional techniques. As the scope of applications increases, demand for quality evaluations of key processes such as powder metallurgy also increases.

Physical testing enables quantitative analysis of supplier quality, adherence to procedures and process performance. Maintaining quality in powder metal fabrication begins with the testing of the powders themselves. Metal powders are tested for correct chemistry, particle size distribution and mechanical properties. Components manufactured by powder metal processes are typically tested for hardness, impact resistance, tensile strength and density. AM part suppliers that develop the procedures to assess end-to-end quality position themselves effectively for growth. Consistency, reliability and proof of performance represent integral elements for industry sectors with a low tolerance for risk such as aerospace, automotive and medical device.